3D Scanning and Printing

Group Task

To check for the printer quality we had to check if it can follow these parameters (reference to the printed group design picture):

01 Nut, Size M4 Nut should fit perfectly – it was not perfect as it looked more of a circle rather than a nut shape.

02 Wave, rounded print – An extra layer was available that required some sanding

03 Star, Sharp Edges -The curves were not sharped and were mildly bended.

04 Name, Complex Shapes - ok

05 Holes, Size 3, 4, 5 mm – the circles were not drawn accurate and diameter were little out of space.

06 minimal Distance: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm – there were a lot of lines were stuck with each other with no distances between them.

07 Z height: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1 mm – It was ok didnt see any difference

08 Wall Thickness: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm -there were a lot of walls stuck with each other with no distances between them.

09 Bridge Print: 2, 4, 8, 16 mm It was ok didnt see any difference

10 Sphere, Rounded Print 4.8mm height It was ok didnt see any difference

11 Sphere Mix, 7 mm height It was ok didnt see any difference

12 Pyramide, 7 mm height It was ok didnt see any difference

13 Overhang: 25, 30, 35, 40, 45, 50, 55, 60, 65, 70° -some of them stuck with each other.

14 Warp, does it bend? no

15 3D Print Font, optimized for 3D printing- Yes

16 Surface, Flatness – print out some rough surfaces where sanding and smoothing are required

17 Size, 100 x 100mm x 23.83 (10mm width) -no comment

18 Spike, minimum Layer Time, 21 mm height from Bottom (include Baseplate) – the spike have no sharp edges at the end more like a rectangular rather than a spike (spear)

19 Hole in Wall, 4 mm diameter, check for proper print – not printed properly the diameter and shape not accurate.

20 Raft Test, raft should be just under the model no comment

21 Retract Travel, check retract settings for longer travel no comment

Onshape

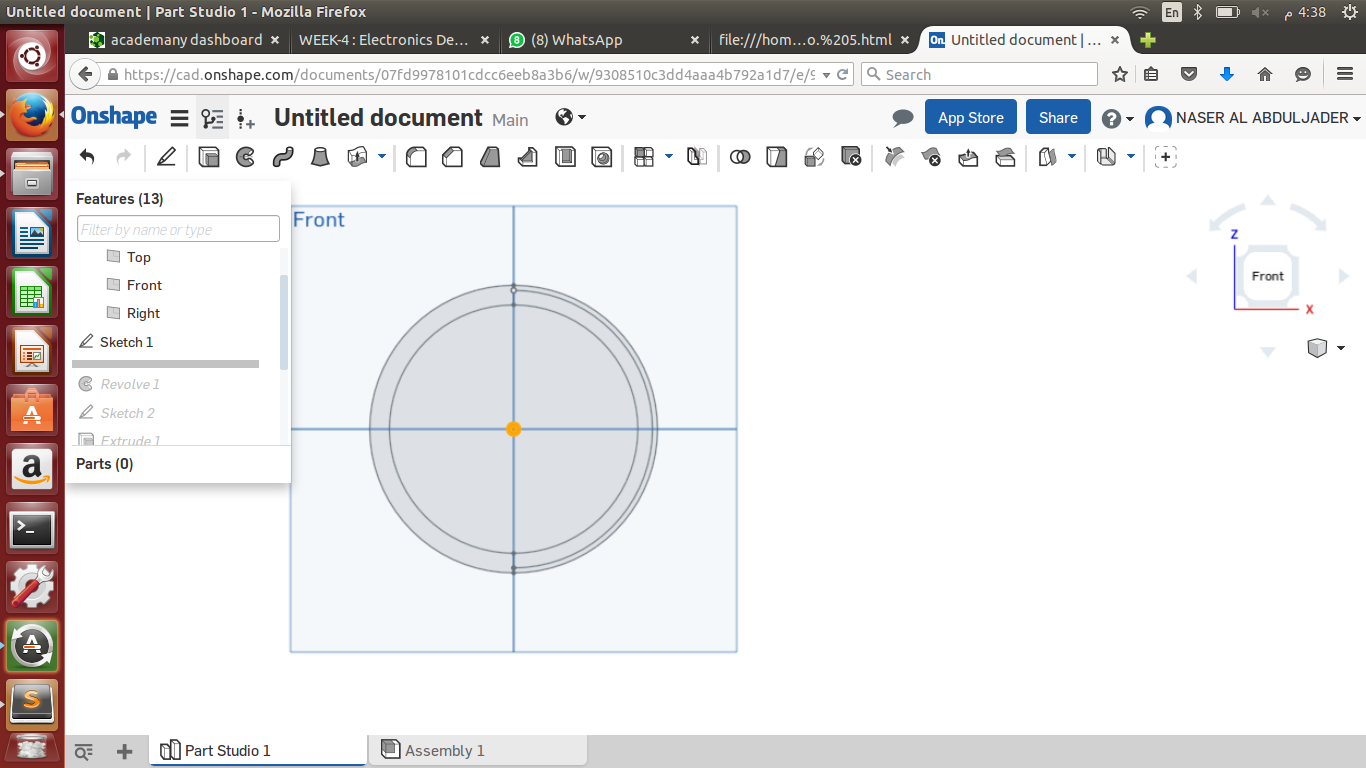

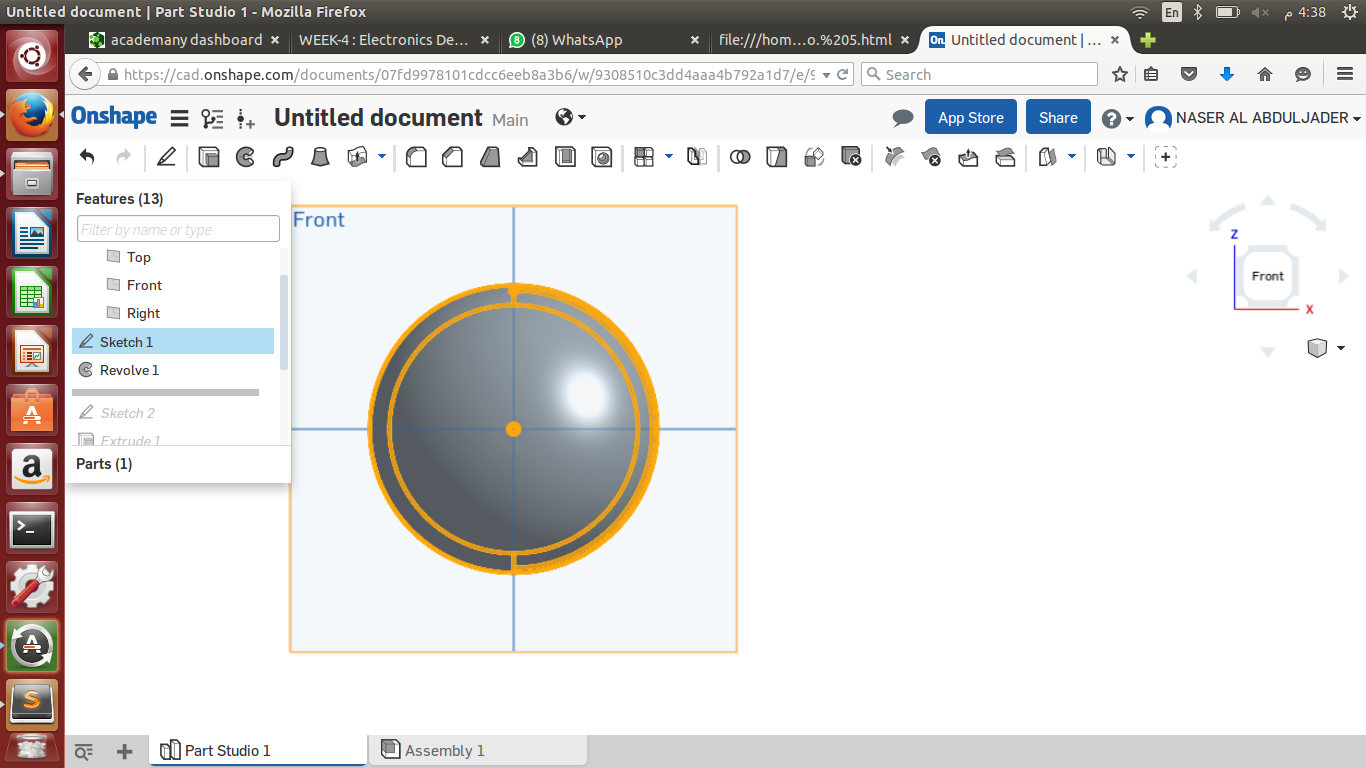

I used onshape for my 3D design and compared to tinkercad I found it difficult and complicated in creating my 3D design.

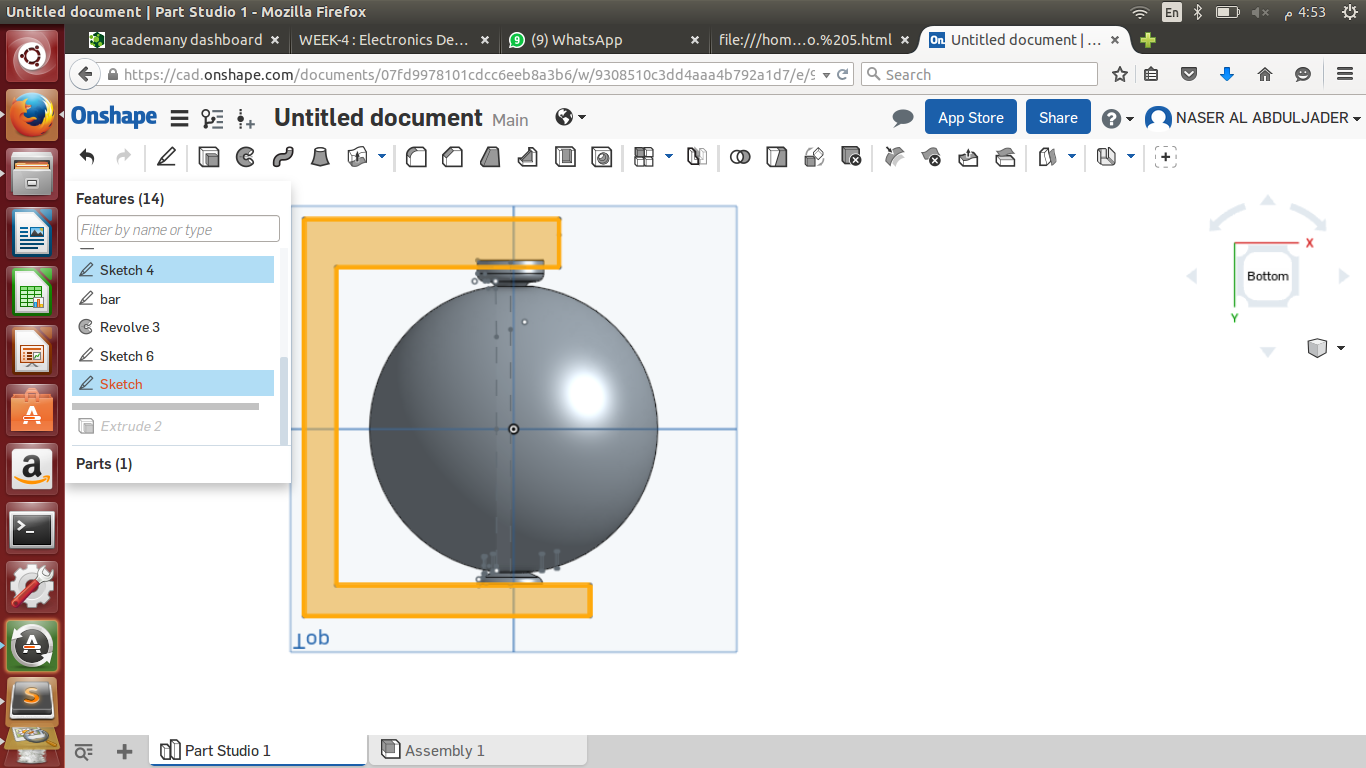

The idea was to create “Saturn planet” but it was complicated to create the ring surrounding the planet based on my colleague previous attempts in their own designs that the printing machine need a base for the printing the material (plastic) before it can print. As such, to avoid any mistake in my printing I changed my design to a somewhat racing course.

The problem with my “racing course” is not subtractive because it can modeled by traditional methods as such I devised a massaging tool based on my initial design.

The link for my 3D 3d design in onshape and also, my original file

massage tool

I save my 3D design as STL then converted in reel vision to fcode that the 3D printer can read it and work on it.

Printing

I took the converted fcode file from the USB to the printer. I Pressed print panel in the printer and my design appeared before printing.

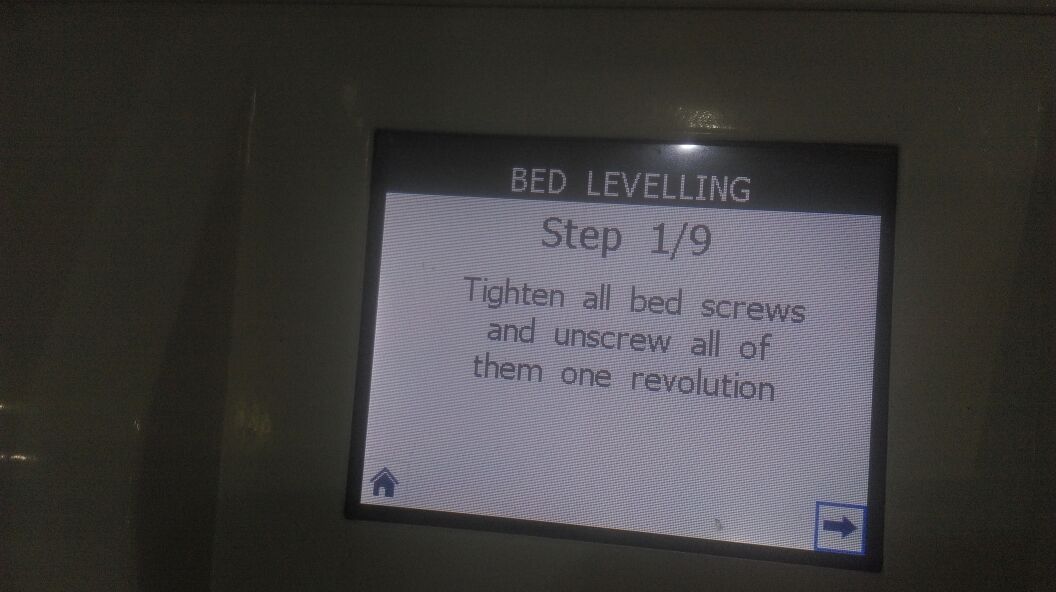

I selected the required heat from the 3d printer for the nozzle “210'C”,the bed temperature "40'C" PLA Filament for my design. It was already leveled due to an option in the 3D printer for leveling the Bed.Then I have to wait for my design to be printed.

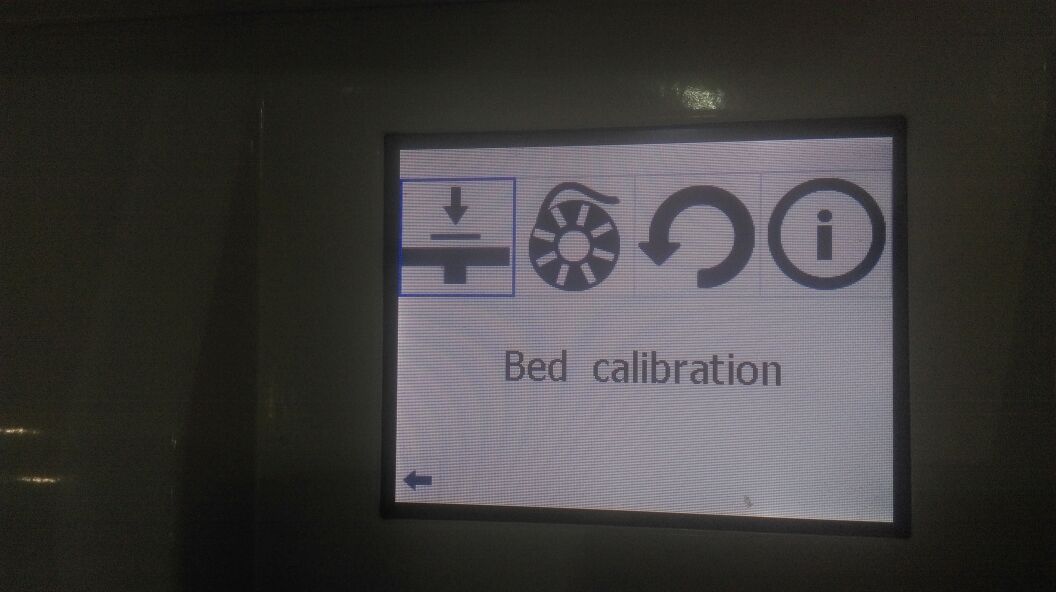

The option that levels the bed.

We have to follow the steps as shows in the pictur to level the bed.

Finally my massaging tool is completed :).

The main benefit of 3D printer is that easy to use especially with the leveling of the bed and the quality of the printing. The main limitation in opinin it is very slow to print and bed size is small 15 cm by 15 cm

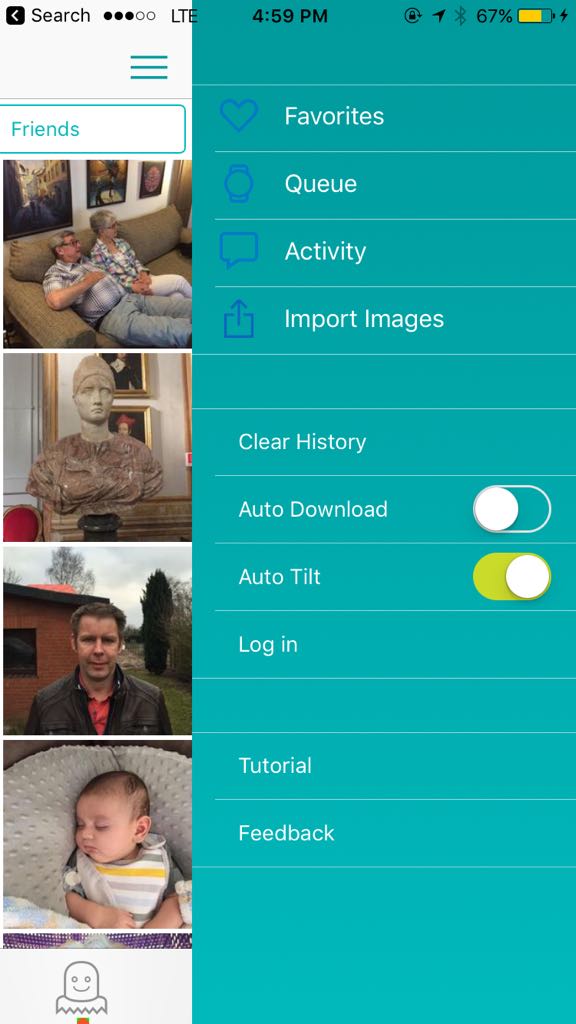

One of my assignment for this week is to scan a 3D object. In our lab we dont have a 3D scan so to achieve the week requirments is by using an application called "Trnio". Trnio can model a 3D scan through my phone and this what I did. The issue with Trnio is that I have to wait for hours for my 3D scan to be completed where the scan must go to the appplication server and then be processed to my phone. After the scan completed they email me my 3D photo and it link where you can find it below.

Using the Scan option in Trnio I decided to scan the Coffee pot. To achieve that I have to scan slowly using my phone camera the entire object.